Foam products are widely used across industries for cushioning, insulation, and structural purposes. Two of the most common types of polyurethane foams are slabstock foam and molded foam, each with unique manufacturing processes, properties, and applications. Understanding the distinctions between these two foam types is essential for choosing the right material for your needs. This article explores slabstock foam and molded foam, their benefits, and where they excel in practical use.

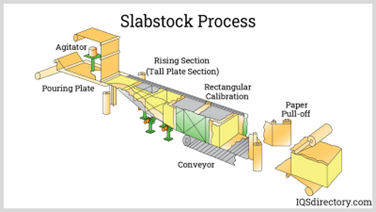

What is Slabstock Foam?

Slabstock foam refers to large blocks or “slabs” of polyurethane foam produced through a continuous pouring process. The foam is cured, cut, and shaped into various forms for use in multiple applications.

Manufacturing Process:

- Continuous Pouring: Liquid polyurethane is poured onto a conveyor system in a continuous manner.

- Expansion and Curing: The foam expands and hardens as it moves along the conveyor.

- Cutting and Shaping: The cured foam is cut into large blocks or sheets for further processing.

Applications of Slabstock Foam:

- Furniture: Upholstery, seat cushions, and mattress toppers.

- Bedding: Mattresses and pillows for enhanced comfort and support.

- Packaging: Protective padding for delicate items.

- Soundproofing: Acoustic panels and insulation.

Advantages of Slabstock Foam:

- Customization: Can be cut to specific sizes and shapes.

- Economical: Cost-effective for high-volume applications.

- Versatility: Available in various densities and firmness levels.

- Scalability: Ideal for producing large quantities of foam sheets or blocks.

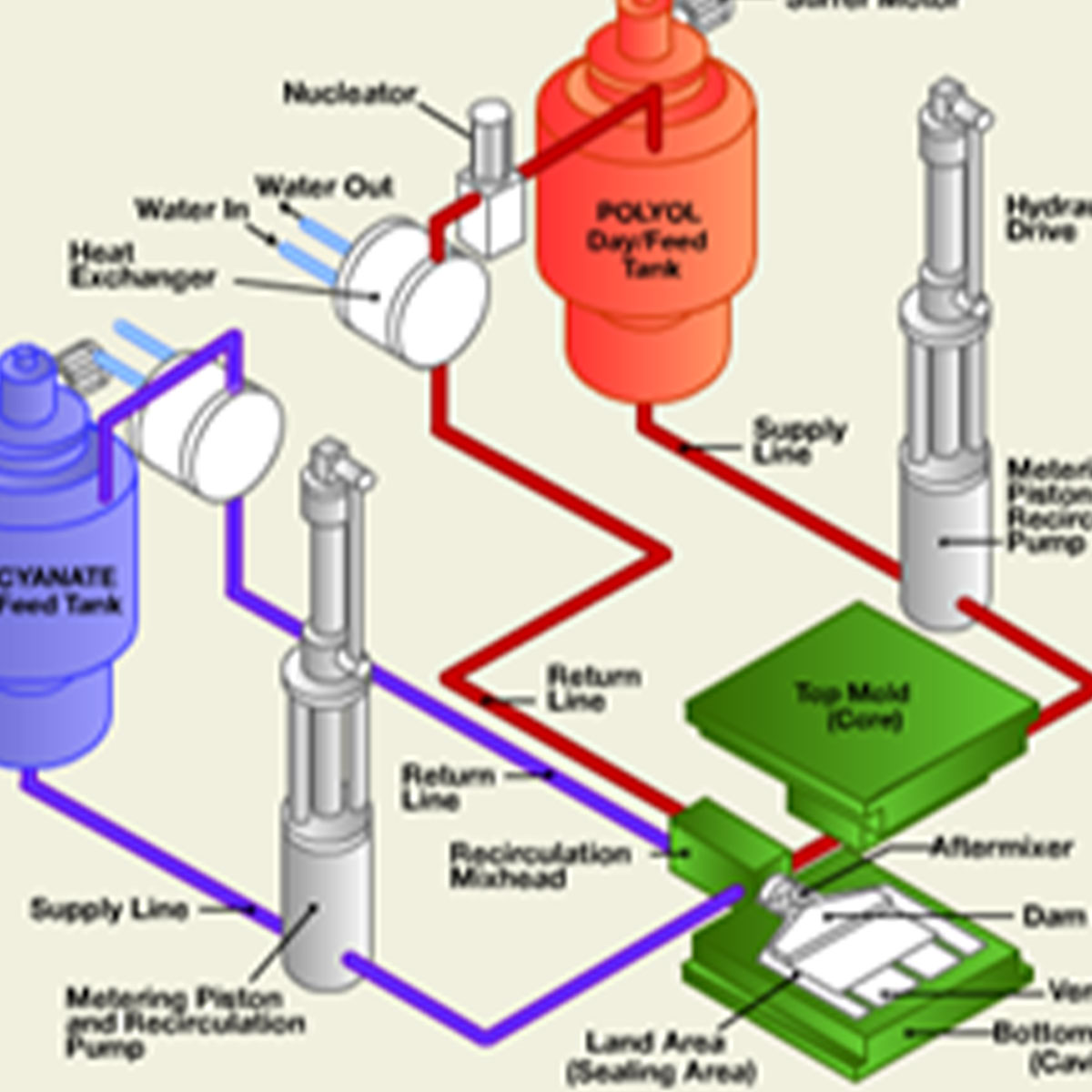

What is Molded Foam?

Molded foam is created by pouring polyurethane into a mold, where it is allowed to expand and take the shape of the mold. This process ensures precise dimensional accuracy and consistency, making it ideal for applications requiring detailed designs.

Manufacturing Process:

- Molding: Liquid polyurethane is poured into a custom mold.

- Expansion and Curing: The foam expands to fill the mold and solidifies.

- Demolding: The molded part is removed, and finishing touches are applied.

Applications of Molded Foam:

- Automotive: Car seats, headrests, and dashboards.

- Medical: Wheelchair cushions and orthopedic supports.

- Office Furniture: Ergonomic chairs and armrests.

- Consumer Goods: Custom-shaped cushions, toys, and protective gear.

Advantages of Molded Foam:

- Precision: Perfect for complex shapes and designs.

- Durability: Higher structural integrity due to the mold’s uniform compression.

- Aesthetic Appeal: Smooth, clean finish right out of the mold.

- Efficiency: Less material waste in production compared to slabstock foam.

Key Differences Between Slabstock Foam and Molded Foam

Feature | Slabstock Foam | Molded Foam |

Manufacturing | Produced in large continuous blocks. | Formed in specific molds. |

Customization | Requires cutting and shaping post-production. | Mold determines the exact shape. |

Cost | Economical for large, simple products. | More expensive due to tooling costs. |

Applications | Ideal for flat or layered products. | Best for intricate, three-dimensional shapes. |

Finish | Requires additional processing for smooth edges. | Comes out with a finished surface. |

Material Waste | Higher waste due to cutting processes. | Minimal waste due to precise molding. |

Choosing Between Slabstock Foam and Molded Foam

When to Choose Slabstock Foam:

- If you need foam sheets or blocks for general-purpose applications.

- When cost-efficiency and scalability are a priority.

- For applications like mattresses, acoustic insulation, or packaging.

When to Choose Molded Foam:

- If you require precision for complex shapes and detailed designs.

- When durability and structural integrity are critical.

- For industries such as automotive, healthcare, and high-end furniture.

Conclusion

Both slabstock foam and molded foam offer unique advantages tailored to different applications. Slabstock foam excels in versatility, cost-effectiveness, and scalability, while molded foam provides precision, durability, and design flexibility. By understanding the strengths of each, manufacturers and consumers can select the ideal foam type to meet their specific requirements.

Whether you’re designing furniture, automotive interiors, or medical equipment, the choice between slabstock and molded foam plays a critical role in ensuring the performance and success of your products