Reaction Injection Moulding (RIM) is a cutting-edge manufacturing process used to produce high-quality, complex parts from polyurethane. This versatile technique allows manufacturers to create strong, durable, and lightweight components for a wide range of industries, including automotive, electronics, and consumer products. In this article, we’ll explore what RIM polyurethane is, how the process works, and its many applications and benefits.

What is Reaction Injection Moulding (RIM)?

Reaction Injection Moulding (RIM) is a high-pressure molding process that involves the mixing of liquid polyurethane resins with a curing agent before injecting the mixture into a mold. The resin undergoes a chemical reaction that causes it to harden and form a solid structure. Unlike traditional injection molding, which uses pre-processed polymer pellets, RIM uses liquid components that react chemically inside the mold.

The process can be adapted to create both flexible and rigid polyurethane parts, making it suitable for a broad spectrum of applications. The resulting components exhibit excellent mechanical properties, including high impact resistance, dimensional stability, and surface finish.

How Does the RIM Process Work?

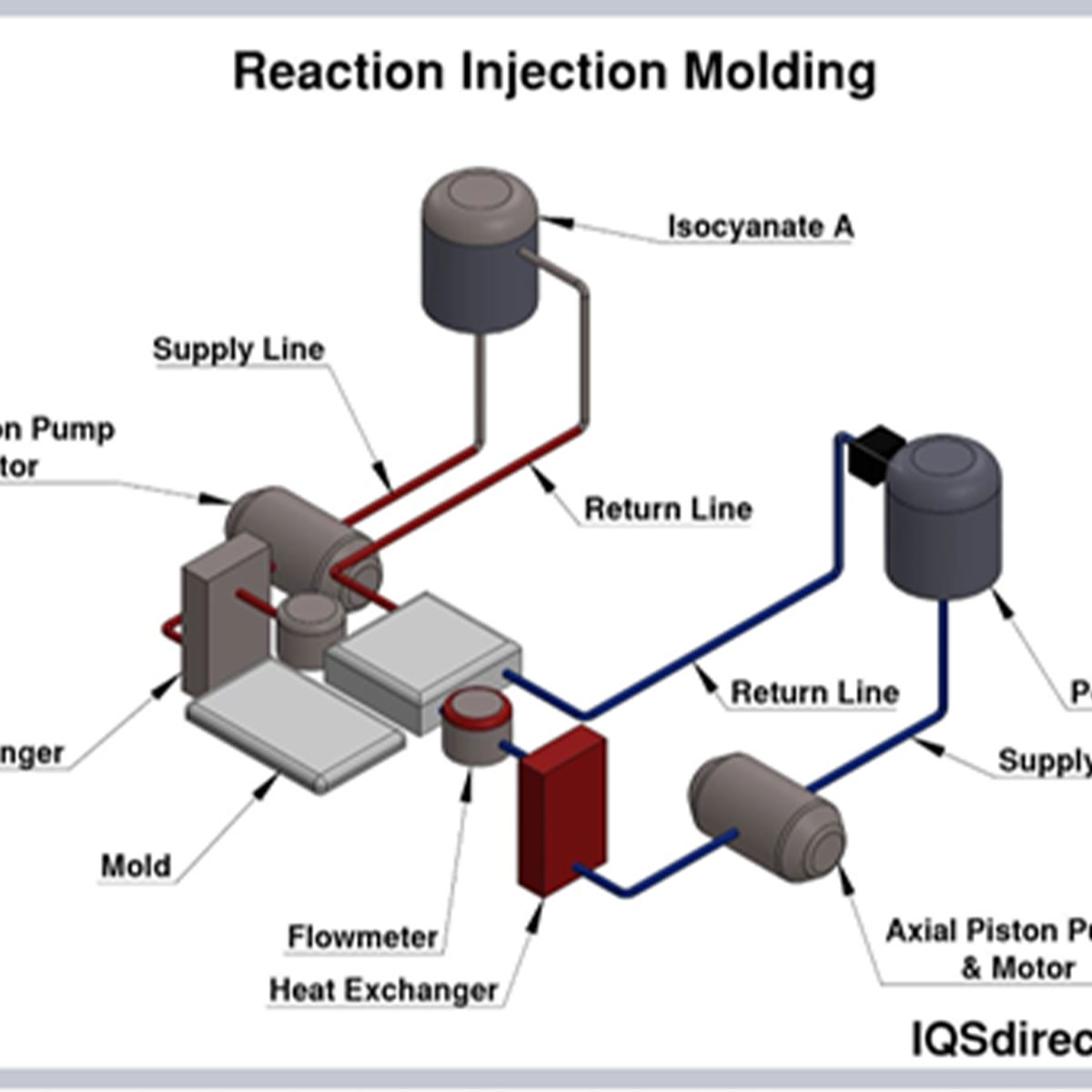

The RIM process consists of several key steps:

- Mixing: The two main components of RIM – a polyol (a liquid resin) and an isocyanate (a curing agent) – are mixed in precise proportions. This chemical reaction is exothermic, meaning it generates heat, causing the material to harden.

- Injection: The mixed liquid polyurethane is injected into a closed mold under high pressure. The mold is typically made of metal and is designed to the precise shape and dimensions of the desired part.

- Curing: As the polyurethane mixture fills the mold, the chemical reaction continues, causing the material to cure and harden. The curing time can vary depending on the material and part design, but it typically takes a few minutes.

- Cooling and Ejection: After the curing process is complete, the part is allowed to cool. Once cooled, the mold opens, and the finished part is ejected.

This process allows for the production of parts with complex shapes and fine details, all while maintaining excellent mechanical properties.

Advantages of RIM Polyurethane

- Design Flexibility: RIM polyurethane can be molded into a wide range of complex shapes, from simple to highly intricate designs. This flexibility is one of the main reasons why RIM is used in industries that require parts with detailed features, such as automotive and aerospace.

- Durability: Polyurethane produced through the RIM process has exceptional mechanical properties. It is highly resistant to abrasion, impact, and wear, making it ideal for applications that require durable parts.

- Lightweight: RIM polyurethane parts are lightweight, which is particularly beneficial in industries like automotive and aerospace, where reducing weight is a priority for fuel efficiency and performance.

- Cost-Effective: Compared to traditional molding processes, RIM is relatively cost-effective, especially for medium to large production runs. The process is highly efficient and can produce high-quality parts quickly, reducing both manufacturing costs and lead times.

- Versatility in Material Properties: The chemical formulation of the polyurethane mixture can be tailored to achieve different material properties, such as flexibility, rigidity, and resistance to chemicals, UV radiation, or extreme temperatures. This allows manufacturers to create parts that meet specific performance requirements.

- Excellent Surface Finish: RIM parts have a smooth and high-quality surface finish, reducing or eliminating the need for post-production finishing processes, such as painting or coating.

Applications of RIM Polyurethane

RIM polyurethane is used across numerous industries due to its ability to produce high-performance parts. Some of the most common applications include:

- Automotive Industry: The automotive sector is one of the biggest users of RIM polyurethane. It is used to create durable, lightweight components like bumpers, fascia, body panels, and interior parts such as dashboards, door panels, and armrests.

- Consumer Products: Many consumer products, such as housings for electronics, appliances, and furniture components, are made using RIM polyurethane. The ability to mold complex shapes makes it an ideal choice for manufacturers of innovative and ergonomic products.

- Aerospace and Aviation: In aerospace, RIM polyurethane is used for producing lightweight parts that meet stringent performance and safety standards. These can include cabin interiors, structural components, and insulation materials.

- Medical Devices: RIM polyurethane is used in the production of medical device parts that require both strength and flexibility. It is commonly used for items like prosthetics, orthopedic supports, and other medical components.

- Sporting Goods: RIM polyurethane is utilized to manufacture lightweight and durable sporting goods such as protective gear, helmet shells, and padding materials.

Conclusion

Reaction Injection Moulding (RIM) is an innovative and versatile manufacturing process that provides a wide array of benefits, including design flexibility, durability, and cost-effectiveness. RIM polyurethane parts are used in a variety of industries, including automotive, aerospace, medical, and consumer goods, to create components that are strong, lightweight, and capable of withstanding demanding conditions.

As technology advances, RIM polyurethane will continue to play a critical role in the development of high-performance, sustainable products. With its ability to meet the needs of modern manufacturing, RIM is poised to remain an essential process for producing complex, high-quality components for years to come.